Author: Andrii Ianiuk, Procurement Director of Gas TSO of Ukraine

The topic of procurement in state-owned companies has become surrounded by quite a few myths; the key one is that it cannot be transparent and effective. Such myths are usually formed by the suppliers themselves, who once had a “traumatic experience” when participating in tenders. Another myth is that the procurement in state companies cannot be as effective as in commercial enterprises. In this regard, I can cite the following analogy: “If you don’t have driving experience or a license, it makes no difference what kind of car you drive – you will still find it difficult to get to your destination.”

The key principles underlying the development of an effective procurement system are the same for both state-owned and private companies. They are transparency, equal treatment of all participants within the procurement process, openness and completeness of information, and a systematic approach. Indeed, the success of a company’s operation on trading platforms depends on how its procurement system is built. Surely, no universal know-how exists. There are, however, some basic principles and proven approaches that work.

Rule No.1 – Put yourself in the supplier’s shoes

I joined the team of Gas TSO of Ukraine exactly one year ago. At that time, the Company had been several months old and was just beginning the transformation of its procurement process. The annual volume of the Operator’s procurements is more than 4% of the total volume of public procurements in the country. This is almost 3 000 positions worth over UAH 50 billion. So, the procurement in Gas TSO is one of the key business functions, and the effectiveness of the entire Company depends on it.

The first thing I did at the new place was to open the tender documentation. I must say that at that time, even for me with my many years of experience in procurement, it was difficult to understand which exactly documents had to be submitted by a supplier in order to participate in a tender. It became clear that “that way” we would not achieve any results. Over the course of a year, we completely restructured the process in order to attract the maximum amount of contractors.

First, we simplified and streamlined the requirements set forth for tender documentation. Therefore, we publish them as separate annexes, following the “checklist” principle, in the most easy-to-understand format. Thanks to simplification and preliminary work with potential bidders, the statistics at GTSOU is almost one and a half times better than the average (3.24 bidders per tender). Sometimes the number of bidders per auction was as high as 12 companies. It is a good outcome.

Second, we have standardized the technical requirements for goods/services as much as possible. Due to the consolidation of requirements, we have a wide range of suppliers and, consequently, savings. And then, for greater competition and transparency, we are planning standardization with the involvement of suppliers.

Third, we have launched market consultations with potential suppliers. The procurement requirements for the key categories are undergoing market analysis prior to the publication of tenders, and this ensures maximum competition in the bidding process.

Constructive partnering with suppliers is important. We develop our own database of suppliers, formed on the basis of available information in the Prozorro system and on trading platforms, working mainly with businesses. Assessment of the counterparty depends on the timeliness of fulfillment of obligations, quality of goods, works and services, prices, business reputation, good faith in performance and absence of breaches of obligations.

Rule No.2 – Build a holistic system and take on responsibility

We commenced the transformation of the organizational structure of the procurement function at the beginning of 2020. The Supply Chain Management model was selected based on the principle of process implementation through effective supply chain management. What does this actually mean? Prior to the transformation, all of the Company’s divisions independently generated technical specifications, qualification requirements, prepared draft contracts, and conducted market research, while the procurement division’s tasks were limited to technical work with the Prozorro platform. Now, the target model assumes that the internal customer only generates the request for procurement and technical specifications, submits the said to the Procurement Division and gets the outputs – goods or services. We relieved other functions from non-core activities, placing on ourselves all the responsibility. And it works.

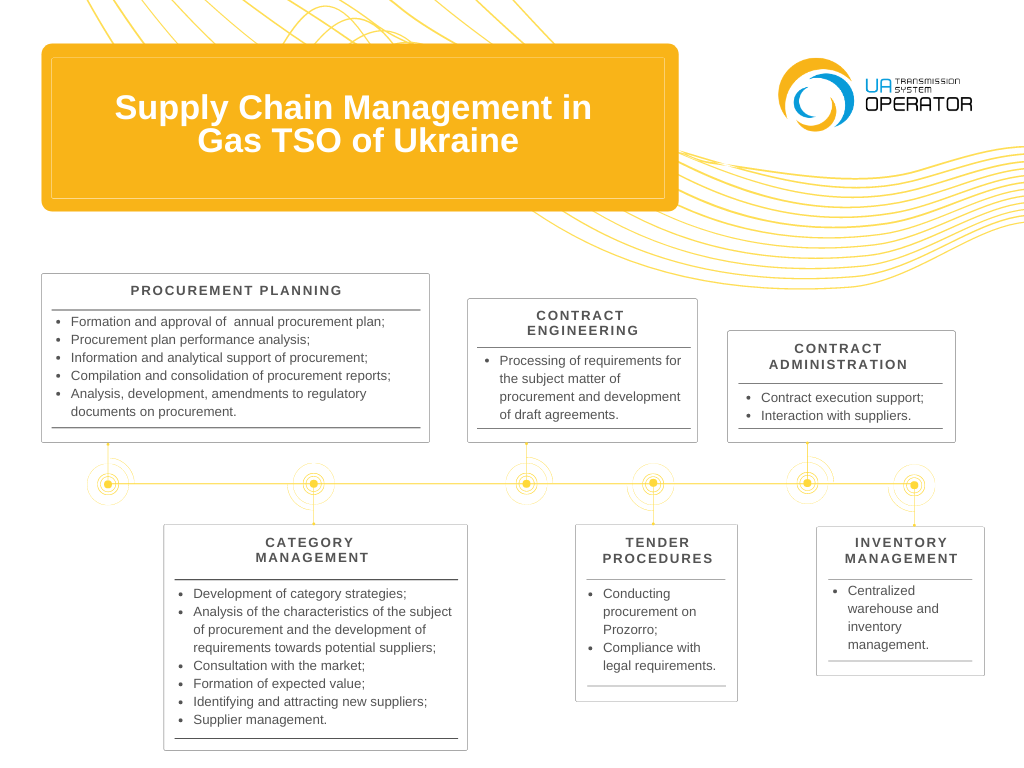

To introduce a new procurement strategy in our Company, we engaged PricewaterhouseCoopers – the consultants of the “Big Four”. Supply Chain Management model is used in many international companies, including those on more complex markets than the oil and gas sector in Ukraine. The new organizational structure is based on six functions: procurement planning, category management, contract engineering, conducting tender procedures, contract administration and inventory management.

click on the picture to enlarge

Not only have the principles of procurement within the company changed dramatically, but also the team has been significantly strengthened: we have attracted 20 more specialists. Taking into account the volume of procurement that the Company has, it is quite logical. We also work with HR on continuous professional development of our procurement team, cooperating with the best business schools, such as KSE.

The results of implementing supply chain management are time and cost savings and improved process efficiency. The next step we plan to take this year is the introduction of the full-scale category management and development of appropriate strategies for all key procurement categories.

Rule No. 3 – Use digital tools

Segments of the economy not affected by digitalization can be counted on the fingers of one hand. And this is understandable: in the age of smartphones, electronic systems, and mobile applications, digital transformation is not even a must-have, but a condition for survival.

This year, we plan to accomplish the transition of procurement to the digital format – from Purchase to Payment. We have already digitized the planning process. The annual procurement plan is formed in accordance with the schedule of maintenance and repair of GTS facilities on the basis of SAP software tools.

By the end of the year, we plan to switch to an upgraded version of the software – SAP S/4 Hana. All the processes will become digital from the initiation of the request for provision to the delivery of the order. The only exception is the tendering on Prozorro. To enable automatic synchronization of SAP S / 4 Hana with Prozorro, we plan to introduce a different software solution.

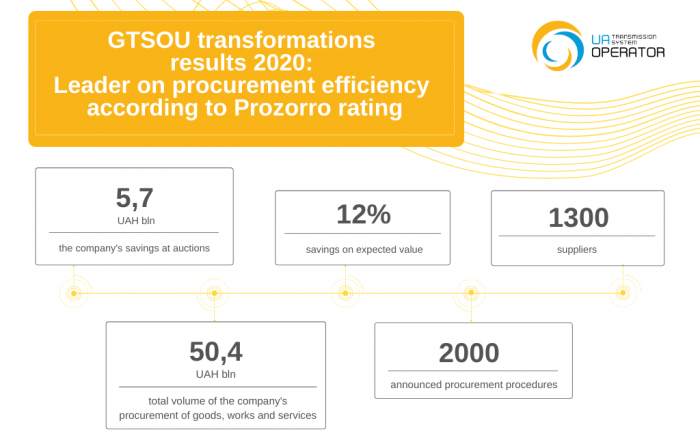

During our first year of work, we went only halfway through the planned transformation. Nevertheless, according to the results of 2020, we were recognized as the leader on procurement efficiency on Prozorro, having conducted 2 000 procurement procedures and saved almost 6 billion UAH. Therefore, the myths about the inefficiency of the public procurement are not justified. Public procurement is not only capable of being, but must be effective. We only need to choose our own transformation path to adopt the best international experience and implement it, taking into account the realities of the Ukrainian market.

click on the picture to enlarge

However, because of this mythologization, it is more difficult for us to work. Last year we did an incredibly difficult job to convince suppliers to come to our tenders, creating clear and transparent conditions for them. Unfortunately, there is a great deal of bias against public procurement. We are trying to change this; the number of participants is increasing with each tender. The situation is somewhat different with some international vendors operating in the oil and gas industry, who supply goods or services that have no analogues. Unfortunately, realizing that customers have no other choice, but to turn to them and being under the influence of myths about non-transparency of public procurement, such companies are in no hurry to the trading platforms. This is a problem, whose solution must be found at the state level, because it affects not only the modernization of the GTS, but also the energy security.