February 22, 2021, Kyiv – Gas TSO of Ukraine has entered into the agreement for in-line inspection services of main gas pipelines with ROSEN Europe B.V., a part of Swiss ROSEN Group, one of the world leaders in engineering and technological solutions.

The agreement provides for the inspection of more than 4.5 thousand km of main gas pipelines of DN 1400 mm with the term of execution until the end of 2024. The total value of the agreement is EUR 6.44 million.

The In-line inspection using ROSEN intelligent tools will make it possible to examine the condition of main gas pipeline metal and welded joints. Timely detection and the elimination of defects reduces the risks of accidents, increasing the reliability of the gas transmission system. It was in 2009, when the previous operator of the GTS performed the last in-line inspection.

The services will be rendered in three stages. The first stage is field works, during this stage the linear part of the main gas pipelines will be cleaned by In-line cleaning pigs, diagnosed using various techniques, and a working report will be also prepared. On the second and third stages, after analyzing the inspection results, a preliminary and a final report will be presented, respectively. The results of the inspection will make it possible to identify concealed defects in the gas pipelines and, accordingly, to prioritize repair work.

“More than 33 thousand kilometers of gas pipelines are on the books of Gas TSO of Ukraine. This year, the Company has planned to spend UAH 7.77 billion on their inspection, diagnostics, repair and maintenance. ROSEN is one of the world leaders in providing In-line inspection services of gas pipelines, and our partnership is aimed at increasing the reliability and safety of the operation of the gas transmission system of Ukraine”, said Sergiy Makogon, General Director of GTSOU.

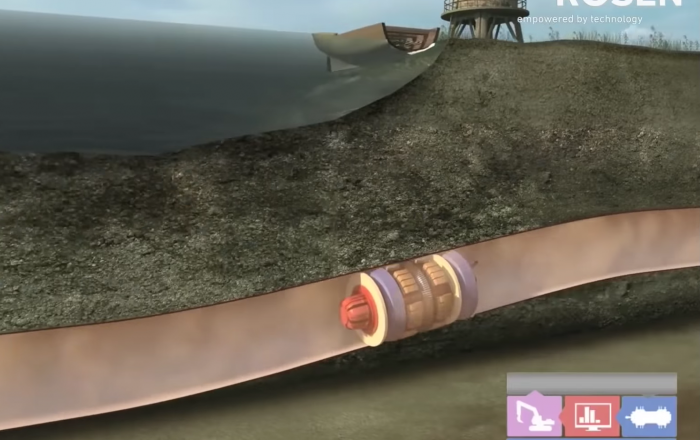

In-line inspection is carried out in order to examine the geometry of gas pipelines, detect defects in the pipe metal and welded joints, and to determine the spatial position of the gas pipelines. A special high-resolution inspection tool – a diagnostic device (pig), which travels in the flow of transported gas, is launched into the gas pipeline. The inspection tool has navigation modules, which allow determining the coordinates of the pipeline axis and in combination with GPS-markers determine the spatial position of the detected pipeline defects, both within the layout and in the profile. Consequently, the information about the location of gas pipeline defects together with the indication of the nature of anomaly such as defects in main gas pipelines, welding seams or geometry features, is recorded in the electronic log.